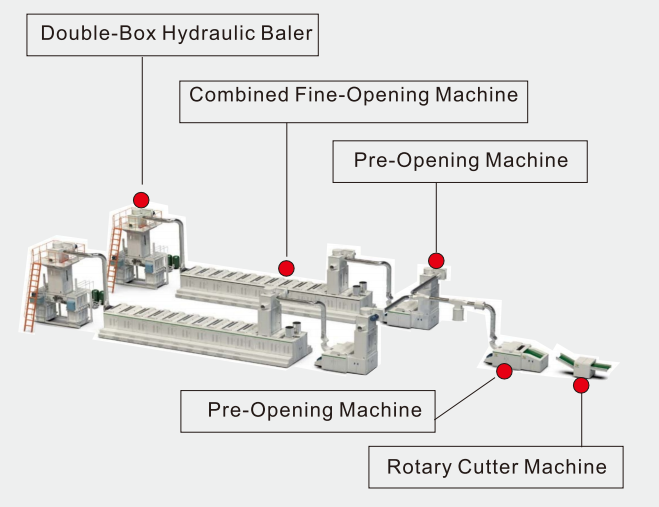

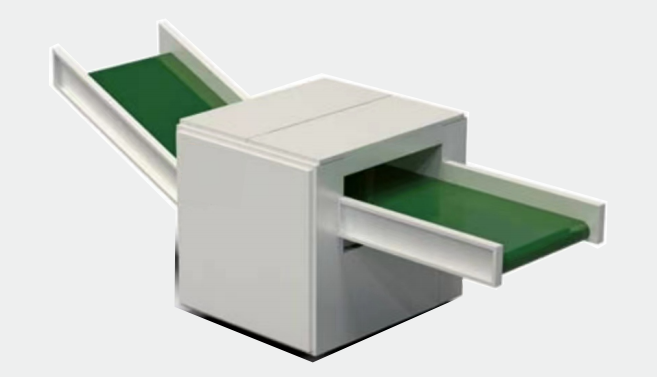

Application:

Cutting machine is a kind of equipment used for pretreatment of raw materials before opening . lt canprocess long strips ofraw materials into small pieces , which is convenient for the subsequent processingof opening machine , Rotary cutter and guillotine cutter are available . lt is suitable for shredding all kinds ofsoft fiber , garment waste material, textile waste yarn , recycled silk , waste clothing , chemical fiber ,glass fiber , hemp fiber , etc .

Feature:

Convenient maintenance , cutting size and length can be arbitrarily adjusted , the whole machine isconvenientto move ,compact mechanism ,stable performanceThe production capacityfrom 500 to 3000kg/ h .

| Productivity | 300-1000kg/h |

| Dia.Of Rotary | 500mm |

| Working Width | 350mm |

| Power | 5.5kw main power,1.5kw feeding conveyor |

| Outsize | 3100*1000*1100mm |

| Weight | about 600kg |

Application:

lt can transport various grades of bundled fibers, feed the materials through the conveyor beltand feed to the latter process through the fan after opening by the high-speed beater This model is suitableforthe feeding offiber raw materials.

Feature:

Laborsaving, convenient and facilitative, stable structure, easy to operate.

| Working Width | 1000mm | Transporting curtain | Aluminium alloy needle curtain |

| Production | 500-700kg/h | MainPower | 3kw |

| Dia.Of Cylinder | 400mm | Outsize | 4430*1606*2390mm |

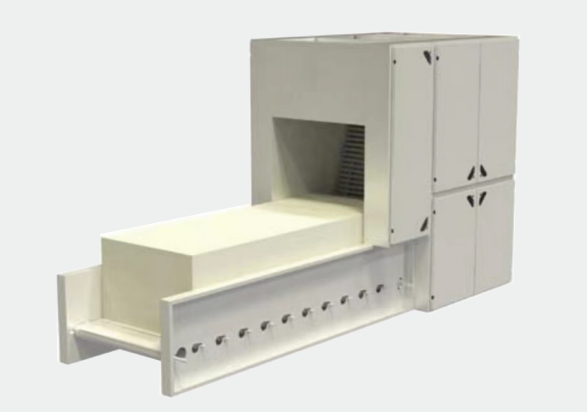

Application:

The textile waste is torn into smallpieces or coarse fibers by the high speed running barbedroller, Under the action of centrifugal force, various impurities can be discharged, so as to get the fiber clothmixcture after preliminary processing.

Mainly used in textile waste and bast&leaffiber processing.

| Name&Type | SK6010Q Pre-Opening Machine | SK6013S Pre-Opening Machine | SK6015S Pre-Opening Machine | SK7515S Pre-Opening Machine |

| Type Of Feeding Roller | Keyboard Type | Four Feeding Roller | Keyboard Type/Four Feeding Roller | Keyboard Type/Four Feeding Roller |

| Working Width | 1000mm | 1300mm | 1500mm | 1500mm |

| Productivity | 300-600kg/h | 400-500kg/h | 800-1000kg/h | 800-1000kg/h |

| Dia.Of Licker-in | 600mm | 600mm | 600mm | 750mm |

| Type Od Licker-in | Pegboard | Pegboard/Wire | Pegboard/Wire | Pegboard/Wire |

| Main Power | 37kw | 37kw | 45kw | 45kw |

| Main Motor Speed | 1450rpm/min | 1450rpm/min | 1450rpm/min | 1450rpm/min |

| Main Motor Inverter Control | Yes | Yes | Yes | Yes |

| Feeding Roller Inverter Control | Yes | Yes | Yes | Yes |

| Outsize | 3491*2001*1307mm | 3526*2300*1390mm | 3716*2340*1307mm | 3716*2340*1478mm |

| Weight | about 3000kg | about 1935kg | about 4000kg | about 5000kg |

Application:

The machine removes impurities from raw materials through the internal big sharp rollerincluding the leaves and seeds in waste cotton, and can also deal with buttons and zippers on waste clothesThe impurity removal rate can reach 70%-80%.The impurities are discharged and collected by centrifugalforce, and the treated fiber enters the next process through the fan for further processing.

The machine needs to work with the pre-opening machine, in order to achieve better clutter removaleffect.

| Processing Capacity | 500-700kg/h |

| Roller Type | Double Sharp Roller |

| Removal Rate | 20-30% |

| Power | 4kw |

| Outsize | 2200*1060*4190mm |

| Weight | 2000kg |

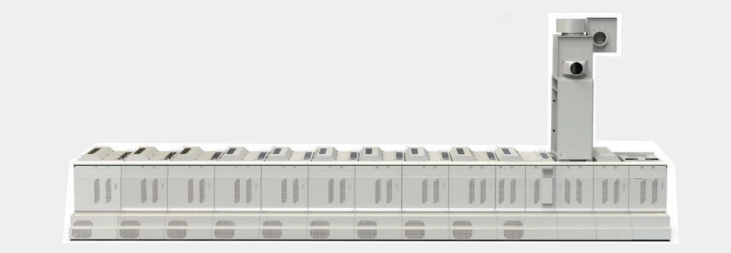

The Fine-opening production line consists ofthe SK 400 series and the SK 250 series. These two type machineuse diferent types of wire to carding the materials after pre-opening to get better spinnable recycled fiber.

The device needs to be used with pre -opening machine to achieve better results.

Feature:

Using double-side air suction structure in dust cage, which is an important technicalinnovation for ourcompany. This design to replace the traditional single-side suction design, can make us get more flat, evencotton layer, get better quality fiber.Using down draft suction design, no exposed pipes, which is better to make cleaning work and easy to maintain.Using backward feeding, it can effectively improve fiber uniformity and spinnability of recycled cotton.Add cotton laver detecting and breakage warning, which is improve work efficiency and reduce failure rateUsing material accumulate detection and automatic cleaning function, which can ensure fiber quality andimprove work efficiency.

| Name&Type | SK40135 Fine-Opening | SK4015S Fine-Opening Machine | SK2513D Fine-Opening Machine | SK2515D Fine-Opening Machine |

| Type Of Feeding Roller | Four Feeding Roller | Four Feeding Roller | Single Feeding Roller | Single Feeding Roller |

| Working Width | 1300mm | 1500mm | 1500mm | 1500mm |

| Productivity | 300-400kg/h | 400-500kg/h | 300-400kg/h | 400-500kg/h |

| Dia.Of Licker-in | 400mm | 400mm | 250mm | 250mm |

| Type Od Licker-in | Wire | Wire | Wire | Wire |

| Main Power | 11kw | 11kw | 7.5kw | 7.5kw |

| Main Motor Speed | 1450rpm/min | 1450rpm/min | 1450rpm/min | 1450rpm/min |

| Main Motor Inverter Control | Yes | Yes | Yes | Yes |

| Feeding Roller Inverter Control | Yes | Yes | Yes | Yes |

| Outsize | 1350*3469*1782mm | 1350*3669*1782mm | 1060*3469*1782mm | 1060*3669*1782mm |

| Weight | about 1500kg | about 1800kg | about 1200kg | about 1500kg |

SK series Double-Box Hydraulic Baler is a new generation of hydraulic baler independently developed byour company, which is mainly suitable for the packaging and processing ofrecycled cotton, falling cottonand other fibers.

Using double cotton box to feed cotton, double box packaging, can effectivelyimprove the efficiency ofpackaging.

The addition ofliquid spray device can meet the customer's need to add auxiliary solvent when fiberpackaging.

| Bale Size | 1000*600*800mm |

| Bale Weight | 120-150kg/bale |

| Productivity | 46/h |

| Main Power | 7.5kw |

| Dia.of Oil Cylinder | 120mm |

| Outsize | 3610*2200*4900mm |

| Weight | 3500kg |

Copyright © SUNKING industry (Shanghai) Co., Ltd. Support :Raise Address:Room838,No.1877,Caoan Public Road, Jiading District,Shanghai City Record:沪ICP备2021016228号-1